Pultrusion

- Home

- Pultrusion

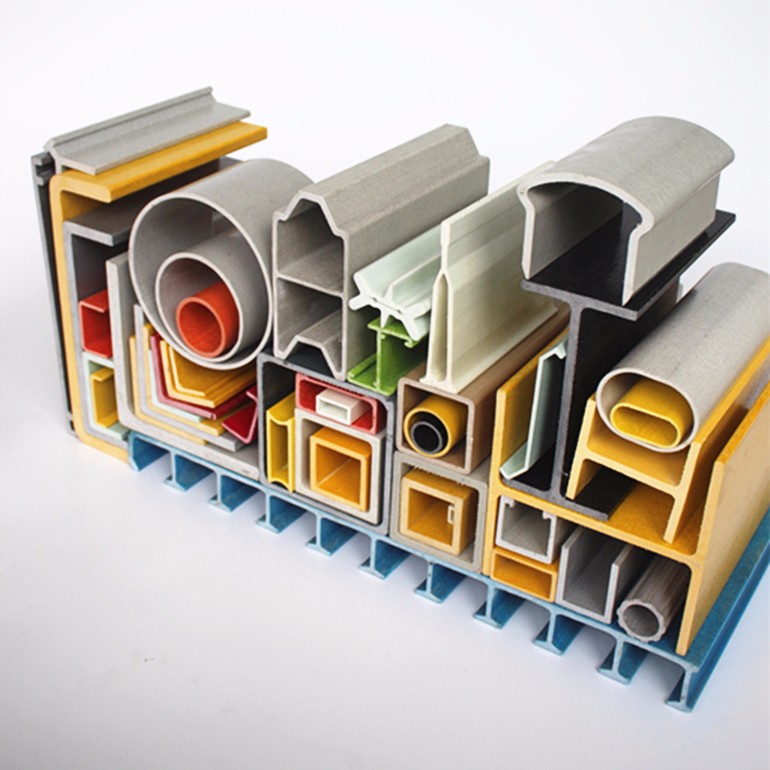

ATLAS Composites Private Limited offer a wide range of pultrusion products from Pultrusion process. Pultrusion is a continuous composite fabrication process where continuous reinforcing fibres are impregnated with thermosetting matrix and are pulled through a heated die to from composite profiles. It has the Capabilities to run continuously with constant cross section profile with the mass production volume.

Due to regularity of cross-section, resin spreading, fiber circulation & arrangement, brilliant composite structural materials can be fabricated by pultrusion. The profiles produced with this process can complete with traditional metal profiles made of steel & aluminum for strength & load.

The process is cost effective for high volume production of constant cross sectional parts like C Channel, Square Box Pipe, Rectangular Box Pipe, Equal Angle, Unequal Angle, I Beam, H Beam, Round Pipe, Half Round Pipe, Rod, etc.

Pultruded Structural profiles are being used in almost all Industrial segments. The major products/application of Pultruded Profiles are :

- FRP cable trays

- FRP walk ways, Stair case and Railings.

- Bridges

- FRP Pultruded Grating.

- FRP cable Tray (Perforated and Non Perforated)

- FRP Ladders

- Ladder type Cable Trays with Fittings

- FRP Fencing.

- FRP Deck Panel.

FRP Pultruded & Hand Moulding Grating

Being trusted FRP Pultruded & Hand Moulding Grating manufacturers in India, we are popular for unmatched quality standards and on-time deliveries. We offer highly innovative product solutions to our clients based on latest tools and techniques.

This is our experience only that we are able to deliver precise FRP Pultruded & Hand Moulding Gratings to our clients. Our modern FRP gratings have smartly replaced the traditional products. Today, all of the products are manufactured or prepared by advance manufacturing process and quality designing standards.

Why to choose FRP Pultruded & Hand Moulding Gratings from ATLAS Composites Private Limited?

- Our products are corrosion resistant, 100 percent environmental friendly and safe in use.

- They are always prepared with advance manufacturing techniques. Hence, scrap content is almost zero.

- We make sure that our FRP gratings should be lighter in weight so they can be installed or handled with ease.

With our experience and industry knowledge, we have acquired trust and confidence of our customers with our superior product range and high quality of services. We also give custom solutions to our clients that make us most reputed FRP Pultruded & Hand Moulding Grating manufacturers in india and worldwide.

Further, our products are tested on various quality parameters for mechanical and physical properties to make sure that end product suits your project requirements perfectly. The customized product solutions for FRP gratings make our product pretty much suitable for varied industrial applications.

For customized product solutions, you just have to share your project requirements with us and get innovative product solutions as required.

- Good Corrosion and Weather Resistance

- High Physical and Mechanical Strength

- High Strength to weight ratio

- Highly Durable

- Lower electrical & thermal conductivity

- Good adaptability & dimensional stability

- UV resistant, Aesthetically appealing, Flexibility in design, Light in Weight and hence easy to handle and install

- Sturdy and Structurally Stable

- Non Skid Surface

- Economical & cost effective

Size:

- Standard: Width – 1200mm , Length – 2400mm

- Standard Thickness: 25mm , 38mm & 50mm

Design Standards:

- As per customer specifications

- ASTM D 3917 – 96

Quality Specifications

- As per ASTM D 3917-96

- OSHA

Technical Specification:

Our FRP Pultruded & Hand Moulding Grating supplied in it’s length, width & height as per customer requirements.

Material of Construction

- FRP Pultruded & Hand Molding Sections with Polyester Grade Resin composition with Fiberglass.

FRP Cooling Towers

Salient Features

- Good Corrosion and Weather Resistance

- High Physical and Mechanical Strength

- High Strength to weight ratio

- Highly Durable

- Lower thermal conductivity

- Good adaptability & dimensional stability

- UV resistant, Aesthetically appealing, Flexibility in design, Light in Weight and hence easy to handle and install

- Ease of Maintenance with Zero Downtime

- Economical & cost effective

Technical Specification

Our FRP Cooling Towers having a wide range of applications and sizes.

Material of Construction

- FRP Moulded using Polyester Grade Resin with Fiberglass

- PVC Fills

Design Standards

As per CTI (Cooling Technology Institute)

Quality Specifications

Qualification as per CTI (Cooling Technology Institute)

FRP Cable Trays

Salient Features

- Good Corrosion and Weather Resistance

- High Physical and Mechanical Strength

- High Strength to weight ratio

- Non Conductive & Non Magnetic

- Full Ventilation

- Highly Durable

- Lower thermal conductivity

- Good adaptability & dimensional stability

- UV resistant, Aesthetically appealing, Flexibility in design, Light in Weight and hence easy to handle and install

- Ease of Maintenance with Zero Downtime

- Sturdy and Structurally Stable

- Economical & cost effective

Material of Construction

- FRP Pultruded Sections with Polyester Grade Resin composition with Fiberglass.

Technical Specification

Our FRP Cable Tray having two types:

- Perforated Type Cable Tray

- Ladder Type Cable Tray

Design Standards

- NEMA FG-1:1993 Rev. 1 (1994)

- PR EN 13709

Size

- Width: 50mm/75mm/100mm/150mm/ 200mm/300mm/400mm/450mm/500mm/ 600mm/750mm/ 900mm

- Length: 3 meter

Quality Specifications

- As per NEMA FG-1:1993 Rev. 1 (1994)

- As per PR EN 13709

- As per ASTM D 3917-96